Biological plants

Biological depuration plants are particularly suggested to

treat wastes from civil applications and industrial realities

whose wastewaters would be degradable due to oxidation

processes by organic microorganisms.

This type of treatment can be applied on different sizes,

from the small civil ones to the large industrial ones, until

arriving to consortium plants in service for the community.

It will be the responsibility of our technical department to

identify the best solution for the examined reality,

choosing equipments and components with the maximum

reliability through time, without omitting the low cost of

management and operation.

Membrane biological reactors

The membrane biological reactors (MBR) come from the coupling of

traditional suspended biomass processes with filtration processes on

micro porous or ultra porous membranes, depending on the nominal

size of the pores.

The membrane biological reactors (MBR) come from the coupling of

traditional suspended biomass processes with filtration processes on

micro porous or ultra porous membranes, depending on the nominal

size of the pores.

The major advantages of this technology are found in the possibility to

eliminate the sedimentation unit at the end of the biologic sector and all

management and operational liens related to it. The substitution of the

sedimentation sector with a membrane filtration sector involves:

- a significant reduction in planimetric encumbrance of the filtration plant;

- the ability to manage the biological process in a totally independent way from the fluctuations of hydraulic load;

- the reduction of excess sludges;

- the elimination of sludge sedimentation problems usually found in conventional activated sludges plants;

- the significant improvement of the qualitative characteristics of the wasted water.

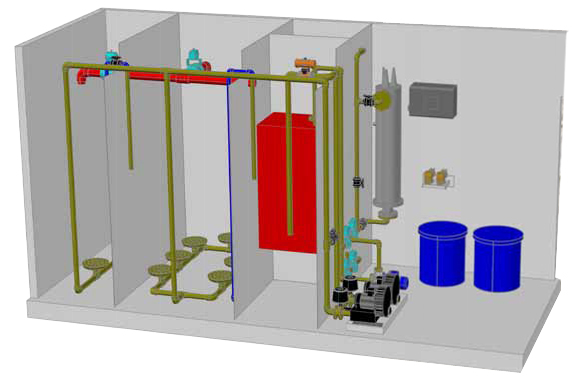

MBBR waste water treatmen plant

The MMBR sewage treatment plants are formed by biological reactors in which microorganisms flourish on media support, dispersed and suspended in the wastewater. The biofilm that is formed on these supports is a function of the organic load associated with the incoming wastewater.

The MBBR technology is particularly suitable for the extreme flexibility of layout and for the simplicity and efficiency of the process, they are used in municipal intensive systems, extensive lagoons, fish farms, food industries, paper mills and chemical plants.

The MBBR reactors can be made with or without recirculation of the sludge from the secondary sedimentation tank, the movement of the elements is ensured by the system of air injection or by mechanical mixers..

The main features of the moving bed reactors can be summarized as follows:

- Operate continuously

- Have limited load losse

- Have a good versatility in the management phase

- Save spacing system